Toughening methods for silicon nitride ceramics?

Summary: Silicon nitride ceramics, as a high-temperature structural ceramic, have become quite common in daily life, and their range of applications is also very broad.

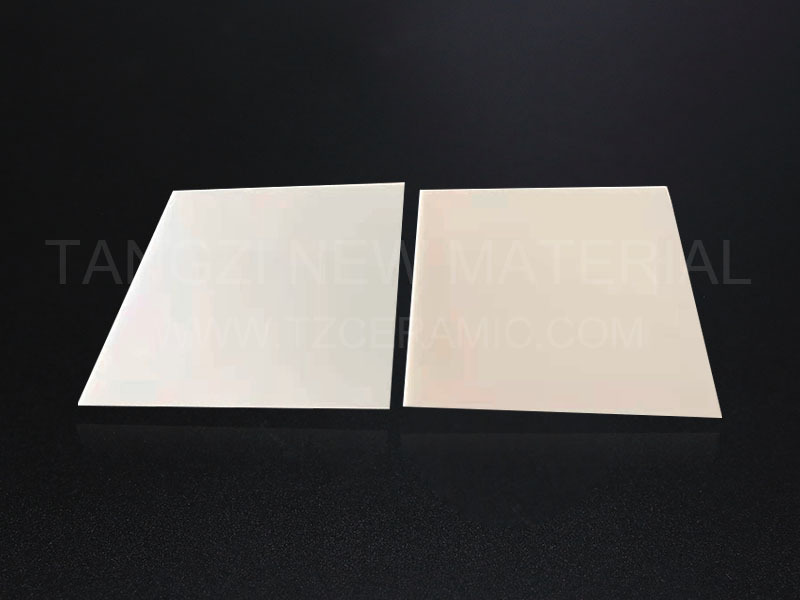

Silicon Nitride CeramicsAs a high-temperature structural ceramic, it has become quite common in daily life, and its range of applications is also very broad. Due to its characteristics of high strength, good thermal shock resistance, and low high-temperature creep, it has become one of the excellent engineering ceramics. Now, let me talk about the toughening methods of silicon nitride ceramics for friends.

When using silicon nitride ceramics, there are quite a few knowledge points we need to understand in advance. First, you should know that its particle toughening involves adding certain particles with high elastic modulus to the Si3N4 material, such as SiC, TiC, TiN, etc. These are actually more specialized knowledge points, but since you want to use it, it is still necessary to grasp them. The particle toughening of silicon nitride ceramics is independent of temperature and can serve as a toughening mechanism at high temperatures. However, this method can only achieve a toughening effect of 40%-70%, and its toughening effect is not very significant. Today, what I have said here should be understood in the future. In addition, there is another method called phase transformation toughening. This refers to the dispersion of zirconia particles in the Si3N4 matrix, and it is induced by stress-induced phase transformation from tetragonal to monoclinic phase, resulting in about 5% volume change. In this case, it can counteract external stress and also prevent crack propagation, achieving the purpose of toughening. Here is a reputable silicon nitride ceramic manufacturer; friends who want to order this product might as well choose here.

Additionally, it is also important to know that silicon nitride ceramic fibers refer to the composite toughening of Si3N4 ceramics with long fibers such as C and SiC. At this time, its mechanism mainly involves crack deflection or branching, pull-out effect, and bridging effect. The self-toughening here mainly refers to adjusting the material composition and controlling the preparation process conditions. This aspect of knowledge is also quite important. In this case, various mechanisms similar to fiber toughening can be obtained to achieve the effect. If there are any questions you do not understand, you can call our Tel for consultation at any time. There are online customer service personnel here to assist you, and they will patiently answer any questions you may have. You can also find our contact information on the official website, and you can call directly for consultation.

Online message

* Note: Please be sure to fill in the information accurately and keep the communication unblocked, we will get in touch with you as soon as possible